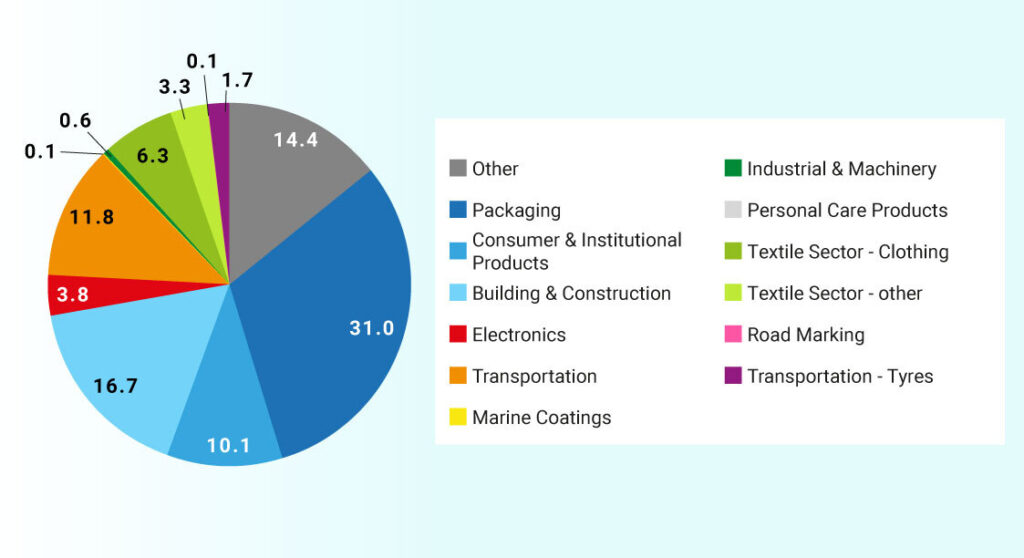

In our everyday lives, plastics surround us in various forms – from the sports equipment we use in our favorite activities to the interiors of the cars we drive, the packaging that protects our food, the containers for our personal care products, and even the components in our electronic devices. To illustrate, check this graphic with data from oecd.org that shows the percentage of use of plastic for different applications.

Surprisingly, despite their widespread presence, less than 9% of the plastics produced annually actually get recycled. In 2019, for example, 368 million tons of plastics were produced. Most of them end up undergoing mechanical recycling processes, like grinding and melt‐processing. Unfortunately, this frequently leads to lower-quality materials that quickly find their way back into the waste stream. This traditional economy resumes itself in “use and discard”.

Now, let’s see why this happens. Polymers ordinarily called plastics are long-chain molecules made up of smaller units called monomers. These monomers link together to form these versatile materials we use every day. Traditionally, plastics are designed to be tough, resistant, and long-lasting, not really with recycling properties. Therefore, when we try to recycle them using mechanical methods, we often end up cutting the chains or changing their chemical structure resulting in materials that are not as good as virgin ones.

Introducing Chemical Recycling

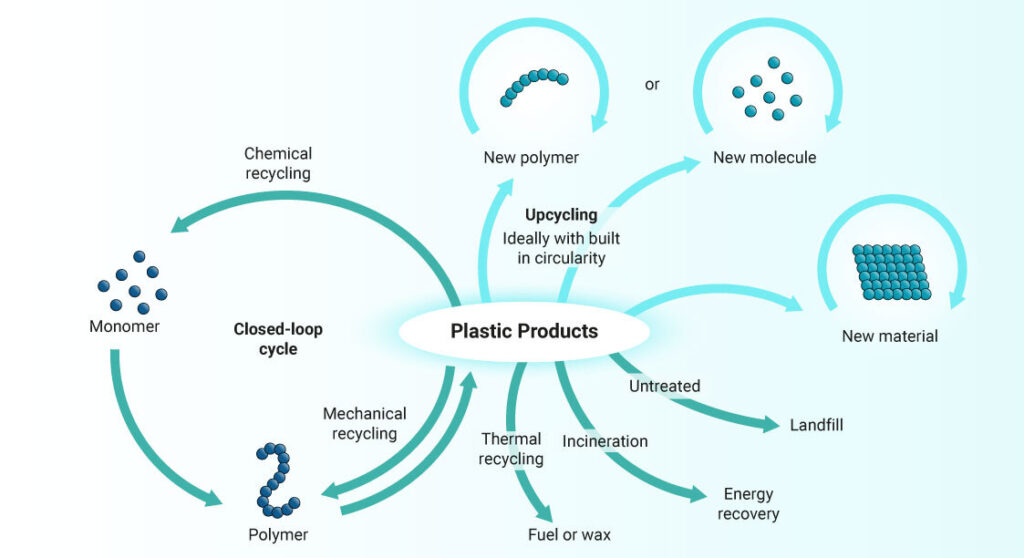

Alongside the familiar mechanical recycling and pyrolysis methods, there is an emerging alternative called chemical recycling. This method consists in breaking down plastics into their original, high-quality building blocks or monomers.

The current challenge is to make this suitable – creating plastics that smoothly go through chemical recycling to become something new. Shifting from just focusing on durability to combining durability with recyclability is a significant move and is considered a major challenge in the field of polymer science and sustainability.

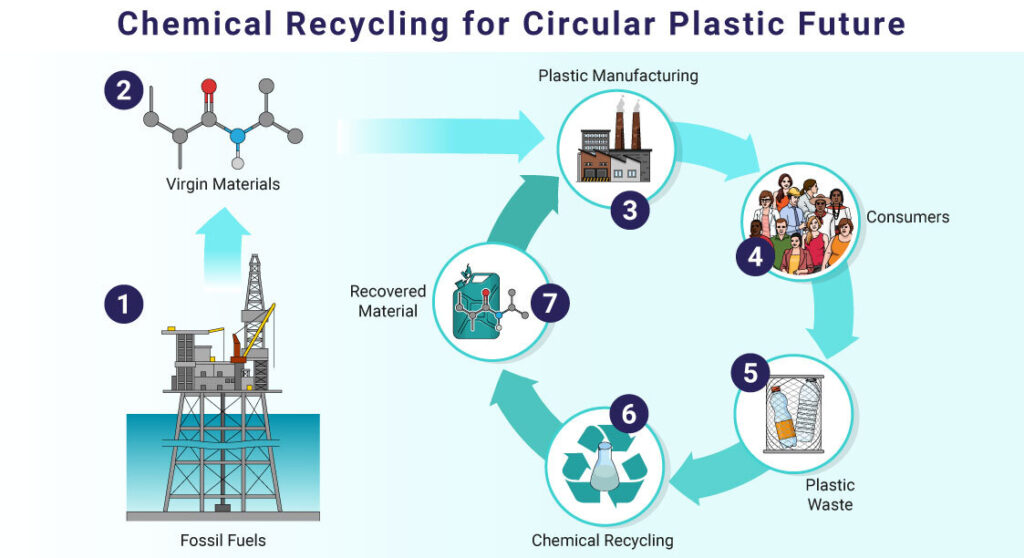

Imagine a world where plastic does not just end up in landfills or oceans but instead goes through a process of transformation, becoming something new and useful each time. That is the dream of a circular economy for plastics – a system where materials are used, reused, and reimagined, breaking free from the traditional linear economy mindset, in which the materials are used once and discarded.

In essence, we are on a mission to revolutionize how we think about and use plastics. It is not just about making them tough; it is about making them smart, sustainable, and a part of our circular journey toward a greener, cleaner future.

History And Evolution Of Chemical Recycling

The concept of chemical recycling has its roots in the early 20th century, but it wasn’t until the late 1970s that the process began to gain attention. Initially, it was seen as a possible solution to the growing problem of plastic waste. However, due to technological constraints and the high cost of implementation, it remained largely unexplored for many years.

The 1990s saw a resurgence in interest in chemical recycling, as concerns about plastic waste and its impact on the environment began to mount. Technological advances allowed for the development of more efficient and cost-effective chemical recycling methods, making it a more viable option for waste management.

In the last decade, chemical recycling has undergone significant evolution. Increased environmental awareness, coupled with advancements in technology, has led to the development of more effective and scalable chemical recycling processes. Today, it is the chemical industry that’s considered a significant part of the solution to the global plastic waste crisis, and its role is anticipated to grow in the coming years.

What Is Chemical Recycling?

Chemical recycling is a groundbreaking process that offers a transformative solution to the challenges posed by traditional waste management. Unlike mechanical recycling, which involves physical processes like grinding and melting to reclaim materials, chemical recycling employs chemical reactions to break down complex polymer structures into their original building blocks. This innovative approach holds immense promise for addressing the growing issue of plastic waste and contributing to a more sustainable future.

The Chemical Recycling Process

Steps involved in Chemical Recycling

The process of chemical recycling can be broadly divided into three steps:

Sorting And Cleaning

The first step in chemical recycling involves sorting and cleaning the plastic waste. It’s crucial to separate different types of plastic, remove any contaminants, and clean the plastic thoroughly to ensure the purity of the resulting chemicals.

Depolymerization

After the sorting and cleaning process, the plastic waste undergoes depolymerization. This process normally involves high temperatures, and solvents and are designed to break down the complex polymers into smaller molecules, i.e. oligomers or monomers.

Purification And Utilization

The resulting chemicals are then purified and converted back into new plastics or other products.

Each of these steps requires sophisticated technology and precise control to ensure the efficiency and safety of the process. But with these in place, chemical recycling offers a viable and sustainable solution to the plastic waste problem.

Key Principles Of Chemical Recycling

Chemical recycling utilizes innovative methods to break down plastics into molecular components for creating new, eco-friendly materials. Through depolymerization, purification, and polymerization, it transforms waste plastics into valuable resources, promoting a circular economy and reducing environmental impact.

Polymer Depolymerization

Through chemical processes like hydrolysis, glycolysis, or solvolysis, polymers can be deconstructed into their constituent monomers, the foundational units from which the polymers were initially created.

Recovery Of High-Quality Materials

Unlike some mechanical recycling methods that might degrade the quality of recycled materials, chemical recycling has the potential to recover high-quality monomers, closely resembling the virgin materials. Then, they can be subsequently polymerized to originate the polymer in the original state.

Versatility In Polymer Types

Addressing Diverse Polymers: Chemical recycling is not restricted to specific polymer types. It can be applied to a wide range of polymers, including thermoplastics and even challenging thermosets, providing a versatile solution for diverse plastic waste streams.

Polymer Upcycling

Creating Value from Waste: Beyond merely recycling, chemical processes open the door to polymer upcycling. This involves converting waste polymers into materials of higher value or even transforming them into entirely new products with enhanced functionalities.

Global Perspectives On Chemical Recycling

Chemical recycling is gaining interest and recognition worldwide as a potential solution to the global plastic waste crisis. Various countries are investing in research and development, policy initiatives, and infrastructure to support this emerging industry.

In Europe, for instance, the European Union’s Circular Economy Action Plan recognizes chemical recycling as a key technology for achieving circularity in the plastic sector. Several European countries, including the Netherlands and Germany, are already home to pilot and commercial-scale chemical recycling facilities.

In Asia, countries like Japan and South Korea have incorporated chemical recycling technologies into their national plastic waste management strategies. China too is exploring this technology as part of its broader push towards a circular economy.

In North America, both the United States and Canada have seen increased investment in chemical recycling projects, with several facilities in operation or under construction.

Despite these positive trends, it’s important to recognize that the global adoption of chemical recycling is still in its early stages. It will require continued technological innovation, regulatory support, and public-private collaboration to realize its full potential.

Innovative Research In Chemical Recycling

The future of chemical recycling is being shaped by innovative research in several areas. One promising line of investigation is exploring new catalysts that can speed up the depolymerization process, thus enhancing efficiency and reducing energy consumption. Another advancement would be to use heterogeneous catalysis and fix these catalysts in flow reactors.

Researchers are also studying the use of biocatalysts, which could offer a more sustainable and environmentally friendly alternative to traditional catalysts.

Another area of innovation is the development of advanced sorting systems, aided by artificial intelligence, that can more effectively separate different types of plastic waste. This technology can significantly increase the efficiency and yield of the recycling process.

Also read: Artificial Intelligence In Science

Additionally, researchers are exploring the use of alternative energy sources, such as solar heat, to power the energy-intensive recycling processes. This innovation could significantly decrease the environmental impact of chemical recycling.

Last but not least, there’s a growing emphasis on life-cycle analysis to evaluate the full environmental impact of chemical recycling processes. Such studies can help identify areas for improvement and guide the development of more sustainable recycling methods.

Challenges And Future Prospects

While chemical recycling holds great promise, challenges such as scalability, cost-effectiveness, and ensuring the purity of recycled materials need to be addressed. Continuous research and technological advancements are crucial for overcoming these hurdles and unlocking the full potential of chemical recycling in revolutionizing the way we manage and repurpose polymer waste. As the field progresses, chemical recycling stands poised to play a pivotal role in reshaping the landscape of polymer sustainability.

Predicted Growth And Trends In Chemical Recycling

As awareness and understanding of the global plastic waste crisis grow, so does the attention towards chemical recycling. There’s a strong consensus among industry experts that chemical recycling is set for significant growth in the coming years.

Part of this growth will be driven by increasing investments in technology and infrastructure to scale up chemical recycling processes. Both private and public sectors are expected to contribute to these investments, reflecting the shared responsibility in tackling the plastic waste problem.

Furthermore, regulatory support for chemical recycling is predicted to increase, with more countries recognizing this method as a key part of their waste management and circular economy strategies. This could lead to policy initiatives that incentivize chemical recycling, such as tax benefits or grants.

Finally, innovation will continue to shape the future of chemical recycling. Advances in catalysts, process technology, and artificial intelligence will enhance efficiency, reduce costs, and improve the quality of recycled plastic products, making chemical recycling an increasingly attractive and viable solution for plastic waste management.

Creating Effective Visualizations Of Polymer And Recycling With Mind the Graph

Crafting visual representations of polymer and chemical recycling processes can be complex. Fortunately, Mind the Graph offers a solution. With its array of tools tailored for scientific schematizing, it becomes easier to illustrate the monomers, reactors, and polymerization and depolymerization processes. By accurately depicting molecular structures, reaction pathways, and material flows, these visuals become indispensable aids to help you communicate your research. They not only enhance comprehension for researchers but also serve as powerful educational tools for students and professionals alike, fostering a deeper understanding of sustainable materials management.

Visually Appealing Figures For Your Research

Mind the Graph: Transforming scientific figures with ease and impact. Create visually stunning figures that captivate audiences, communicate complex concepts, and elevate the impact of your research. Experience the power of visual communication with Mind the Graph and revolutionize your scientific presentations. Sign up for free!

Subscribe to our newsletter

Exclusive high quality content about effective visual

communication in science.